How to test the durability of materials to ensure the stability and comfort of ergonomic chairs in long-term use?

When discussing how to ensure that our ergonomic chairs can maintain a stable structure and provide continuous comfort in long-term use, technical considerations and material durability testing are particularly important. As one of the few furniture manufacturers in China that has both injection molding and caster workshops, we are well aware of the importance of controlling material quality from the source, optimizing production processes, and implementing strict testing processes to create high-quality ergonomic chairs.

Material selection and quality control

1. Procurement of high-quality raw materials

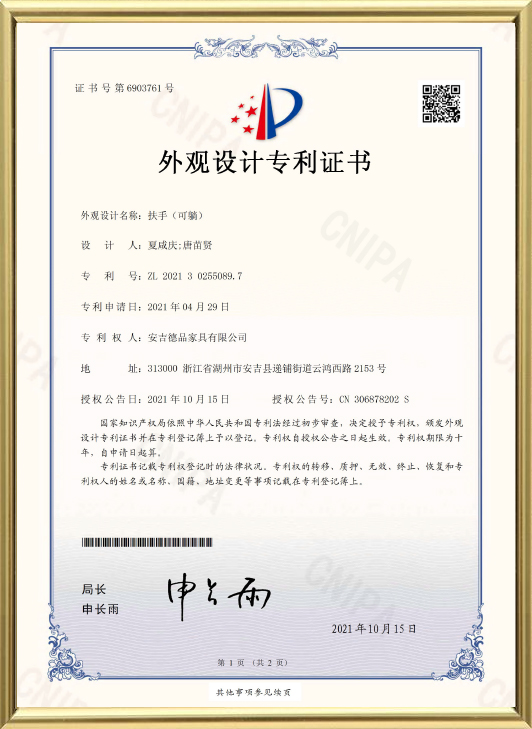

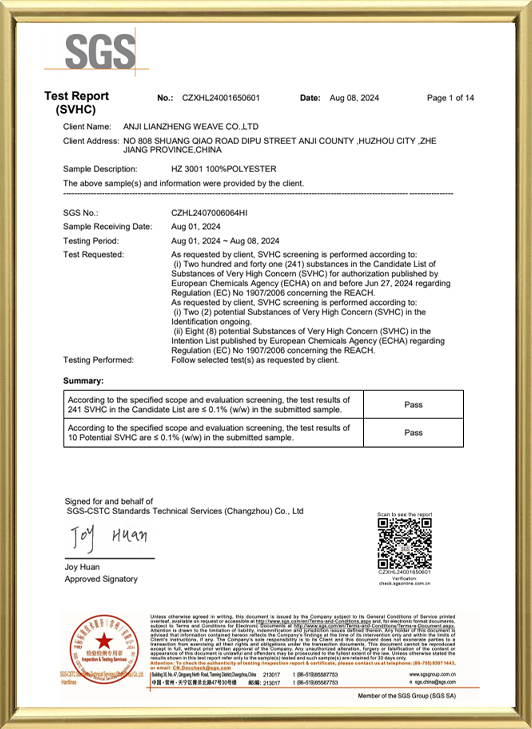

We focus on selecting raw materials that meet international standards from around the world. For the core components of ergonomic chairs, such as seats, backrests and armrests, we use high-strength, high-elasticity, wear-resistant polyurethane (PU) foam or memory foam, which can not only effectively disperse pressure and improve the comfort of long-term sitting, but also have good resilience to maintain a stable shape under long-term use. At the same time, the frame material is made of high-quality cold-rolled steel plates or aluminum alloys, which are specially treated to enhance their corrosion resistance and load-bearing capacity.

2. Precision manufacturing in the injection molding workshop

In the injection molding workshop, we use advanced injection molding technology to accurately control temperature, pressure and injection time to ensure the dimensional accuracy and surface quality of each component. In particular, for the key connectors of the chair, such as five-star feet and gas rods, we use high-strength nylon or ABS materials for injection molding. These materials are not only light in weight and high in strength, but also wear-resistant and corrosion-resistant, providing a solid guarantee for the overall stability of the chair.

Production process optimization

1. Precision assembly and debugging

In the caster workshop, we produce high-quality casters made of wear-resistant rubber or polyurethane materials to ensure the stability and quietness of the chair during movement. During the assembly process, we use a combination of precise automated equipment and manual fine-tuning to ensure the precise docking and tightening of each component, reducing looseness or abnormal noise caused by improper assembly.

2. Quality inspection and monitoring

There are multiple quality inspection points on the production line. From the entry of raw materials to the delivery of finished products, every link undergoes strict quality inspection. We use advanced testing equipment, such as three-coordinate measuring machines and tensile testing machines, to quantitatively evaluate key indicators such as product dimensional accuracy, load-bearing capacity, and durability, ensuring that each product meets or exceeds industry standards.

Durability test method

1. Simulated use test

In order to verify the durability of ergonomic chairs under long-term use, we have designed a complete set of simulated use test solutions. The robot arm simulates the weight and movement of the human body, and performs continuous and high-intensity sitting, rotation, lifting and other operations on the chair to evaluate the chair's load-bearing capacity, durability cycle and structural stability. At the same time, we also simulate user groups of different weights to ensure the wide applicability of the product.

2. Extreme environment test

In addition to conventional use tests, we also test the chair under extreme temperature and humidity conditions to evaluate the performance of the material in harsh environments. These tests include high temperature aging tests, low temperature brittleness tests, and humidity cycle tests to ensure that the chair can maintain stable performance and comfortable experience under different climatic conditions.

3. Fatigue life test

Especially for key components of the chair, such as lifting mechanisms and rotating shafts, we have conducted fatigue life tests. Through tens of thousands of continuous lifting or rotating operations, the wear and performance changes of the components are observed and recorded to predict the actual service life of the product, and the design or material is optimized and improved accordingly.

Combining the company's advantages to enhance product competitiveness

1. Integrated production advantages

With the integrated production capabilities of the injection molding workshop and the caster workshop, we can directly control the manufacturing process of key components and ensure the quality and consistency of the products from the source. This vertically integrated production model not only shortens the supply chain and reduces costs, but also increases the speed of responding to market changes, allowing us to launch new products that meet market demand more quickly.

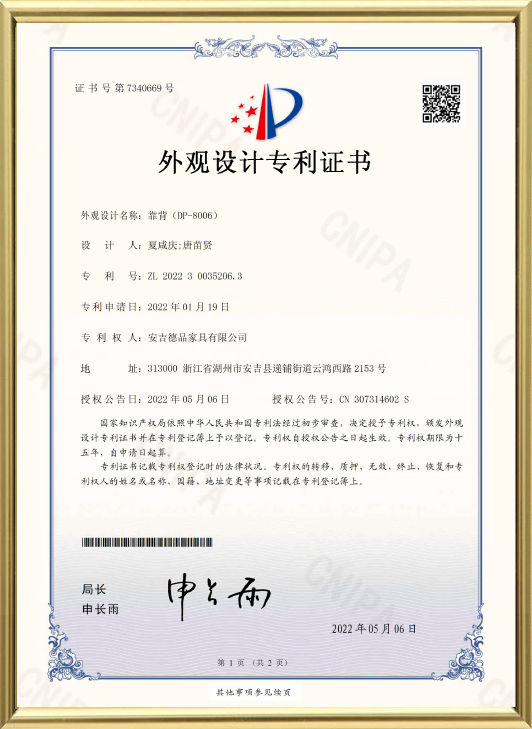

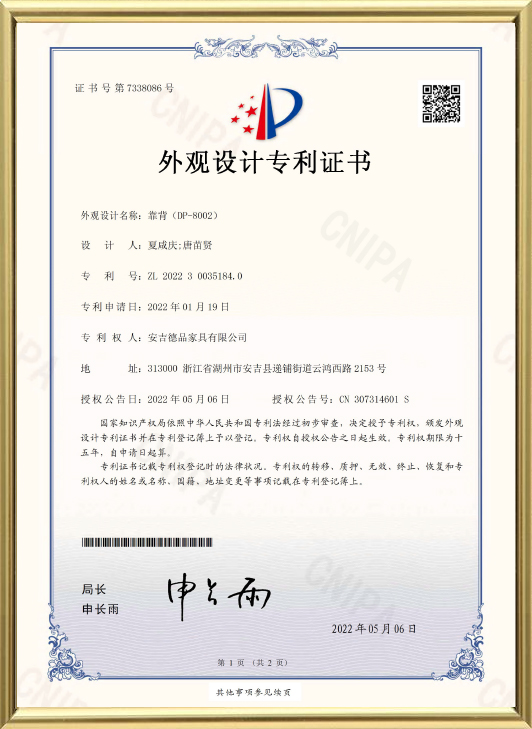

2. Technological innovation and design leadership

We have a professional design team and experienced technicians who are constantly developing and innovating, combining ergonomic principles with advanced material technology to design products that are both beautiful and practical. At the same time, we actively cooperate with well-known designers at home and abroad to introduce cutting-edge design concepts and enhance the market competitiveness of our products.

3. Complete after-sales service system

We are well aware of the importance of after-sales service to customer satisfaction. Therefore, we have established a complete after-sales service system to provide a full range of services such as rapid response, professional maintenance, and regular return visits to ensure that any problems encountered by customers during use can be solved in a timely manner. In addition, we also provide a three-year product quality guarantee, so that customers can buy with confidence and use with comfort.

Through strict material selection and quality control, optimized production processes, scientific durability testing methods, and giving full play to the company's integrated production, technological innovation and design leadership, we have successfully created an ergonomic chair that is both durable and comfortable. These efforts have not only improved the market competitiveness of our products, but also won the trust and praise of our customers.

English

English 中文简体

中文简体 عربى

عربى